Accelerating the Future of Pharma: Our Investment in Persist AI

Congratulations to Persist AI on their $12M Series A!

We’re thrilled to announce that Persist AI has raised $12 million in Series A funding to continue transforming how pharmaceutical formulations are developed. This marks a pivotal moment for the company and the broader healthcare ecosystem. Persist’s platform is already proving to be a game-changer in accelerating the development and manufacturing of complex drug formulations. At Good AI Capital, we are proud to invest in a company that is not only technically exceptional but also deeply mission-aligned with our goal of making healthcare more accessible and efficient through AI.

What Persist AI Does

Persist AI is tackling a mission-critical aspect of the pharmaceutical lifecycle: drug formulation. Every drug, no matter how novel or effective, must be stabilized, packaged, and delivered in a form that works for patients. Persist focuses primarily on long-acting injectables (LAIs), which release medicine over extended periods, sometimes up to a year. LAIs offer dramatic improvements in patient adherence and convenience, particularly in treating chronic conditions like schizophrenia, HIV, and opioid use disorder. However, developing these complex formulations is a slow and expensive process, taking up to a decade in traditional settings. Persist AI is fundamentally changing that timeline through automation, AI, and a platform that reimagines how formulation development is done.

How the Technology Works: AI, Robotics, and Microfluidics

Persist AI is solving the foundational problem in formulation: it’s slow, manual, and lacks data reusability. The company is rebuilding formulation development from the ground up using a first-principles approach—integrating proprietary AI models, purpose-built robotics, and scalable microfluidics to create a feedback loop of intelligent experimentation and prediction.

The process starts with deciding what ingredients to mix and in what ratios. There are countless possible combinations of excipients, solvents, and processing conditions. Persist’s AI narrows this space using generative models to generate first-pass formulations and deep learning models to optimize them based on desired drug loading and release profiles. These models are trained on data collected from Persist’s experiments, simulations, and literature—and they’re tightly coupled to the lab’s automation system, meaning the data can’t just be replicated elsewhere.

Once a set of candidate formulations is proposed, Persist’s custom robotic lab takes over. Traditional automation, built for biology, fails when working with powders and volatile solvents, so Persist engineered its chemistry-focused platform from scratch. Their robotic system performs formulation experiments 30 times faster than a manual lab and uses just a fraction of the materials. With integrated analytics, every run captures high-fidelity data that feeds back into the AI models, making the system smarter over time.

A major enabler of this speed and precision is Persist’s use of microfluidics—the science of precisely manipulating fluids at the microscale, often through channels thinner than a human hair. In the context of drug formulation, this technology is transformative.

Traditionally, producing long-acting injectable particles (such as microspheres or gels) involves large-scale mixing equipment that introduces variability in size and drug release. But with microfluidics, Persist can create uniform, consistent particles with tight control over size and composition—directly affecting how a drug is absorbed and released in the body. This level of precision is crucial for ensuring predictable dosing and long-term therapeutic effectiveness.

Microfluidics also enables continuous manufacturing, rather than relying on slow, error-prone batch processes. It dramatically reduces the amount of drug required for testing—a significant advantage when working with expensive or scarce materials—and allows Persist to run thousands of experiments in parallel. In short, microfluidics turns formulation development into a scalable, programmable, and resource-efficient process.

Perhaps most important, Persist has developed a proprietary membrane-based microfluidic system that works seamlessly across scales. This eliminates one of pharma's most significant pain points: tech transfer. Usually, formulations that work at a small scale must be re-engineered entirely for commercial production because the mixing dynamics change. Persist’s system avoids this by using the same process and equipment from early R&D through to pilot and GMP manufacturing. What once took 1–2 years can now be done in 1–2 weeks.

All of this is wrapped in a Cloud Lab interface, allowing clients to digitally explore formulation strategies, simulate performance, and even launch full development programs remotely. This means pharma companies—large or small—can initiate complex formulation projects without expensive in-house infrastructure.

Persist’s stack of AI, robotics, and microfluidics isn’t just faster—it turns formulation into a programmable, predictable science. That unlocks massive efficiencies and new opportunities across the pharmaceutical supply chain.

Why We Invested in Persist AI

We chose to invest in Persist AI because it aligns squarely with Good AI’s mission: using artificial intelligence to unlock access and efficiency in healthcare. Drug formulation is a bottleneck in the supply chain that often determines whether a drug will ever make it to market or how long it will take. By dramatically reducing the time, cost, and risk of formulation, Persist is helping solve drug shortages, lower development costs, and get medicine to patients faster.

The company’s Cloud Lab model is especially exciting. It democratizes access to sophisticated formulation capabilities, allowing small and mid-sized pharma companies to compete without building expensive infrastructure. For large pharma, Persist becomes a high-leverage R&D partner that can plug into existing pipelines to streamline formulation, optimization, and even manufacturing.

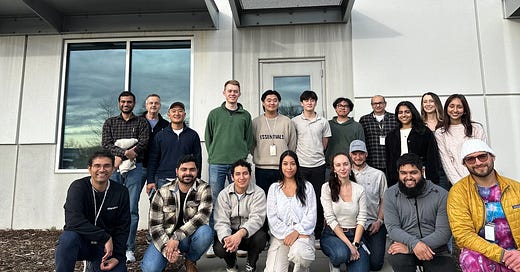

Just as important is the team behind the platform. CEO Karthik Raman and COO Chris Shelner previously worked together at Zymergen, where they built some of the most advanced automation systems in synthetic biology. They bring a rare blend of domain expertise, engineering excellence, and operational discipline. The broader team includes leading scientists in machine learning, bioengineering, and pharmaceutical development, each of whom plays a critical role in the company’s innovation engine.

A Robust Customer Pipeline and Market Traction

Persist’s early traction is not only promising—it’s a clear validation of product-market fit. The company has already signed or is in negotiation for over $6 million in customer contracts, spanning 21 active projects. These include multiple Top 10 pharmaceutical and veterinary companies. Clients have praised Persist for helping them reduce project timelines by over 90% while producing higher-quality data that feeds predictive modeling for future drugs. For example, one generics manufacturer used Persist’s automation platform to run 2,100 formulations in three months—a task typically taking a team of 50 people more than a year to complete. Persist’s ability to generate faster, better insights translates directly into commercial value and customer lock-in.

Persist also structures its engagements to align incentives with customers, combining milestone-based project fees with long-term royalty contracts. This means Persist participates in the upside of successful drugs—a model that has the potential to generate substantial recurring revenue as more drugs developed on its platform reach commercialization.

Strategic Alignment with Eli Lilly and Purdue University

We are especially proud to invest alongside industry leaders Eli Lilly and Purdue University. These partnerships are significant. Eli Lilly has announced plans to more than double its investment in U.S. pharmaceutical manufacturing—an initiative expected to surpass $9 billion. Persist’s capabilities in continuous manufacturing and rapid scale-up align perfectly with this direction, offering a technology platform that enhances quality, efficiency, and flexibility in drug production.

As a Purdue alumnus, I see tremendous synergy between Persist and Purdue’s new Institute for Advanced Pharmaceutical Manufacturing. The institute is focused on modernizing the way pharmaceuticals are made, and Persist’s AI-driven, high-throughput, microfluidic approach represents the very cutting edge of that transformation. These partnerships further validate Persist’s position as a key player in reshaping how medicines are formulated and manufactured at scale.

Looking Ahead

Persist AI is more than a startup—it is laying the foundation for a new era in pharmaceutical development. By integrating AI, automation, and microfluidics, Persist has created a platform that accelerates timelines, reduces costs, and expands access to life-saving medicines. We are honored to partner with Karthik, Chris, and the rest of the Persist team as they scale their impact and bring faster, more innovative drug formulation to the world.

Congratulations on this incredible milestone—we’re just getting started.

References

Beyond the $12M: Revolutionizing Drug Formulation Development at Persist AI

Eli Lilly Plans to More Than Double U.S. Manufacturing Investment

Purdue University Launches Institute for Advanced Pharmaceutical Manufacturing

From Mark Cuban’s CostPlusDrugs to Open-Source Pharma | Good AI Capital

FDA Approves Two Gene Therapies for Sickle Cell Disease | Good AI Capital

Zymergen vs. Ginkgo Bioworks: A Tale of Two Biotech Models | Good AI Capital